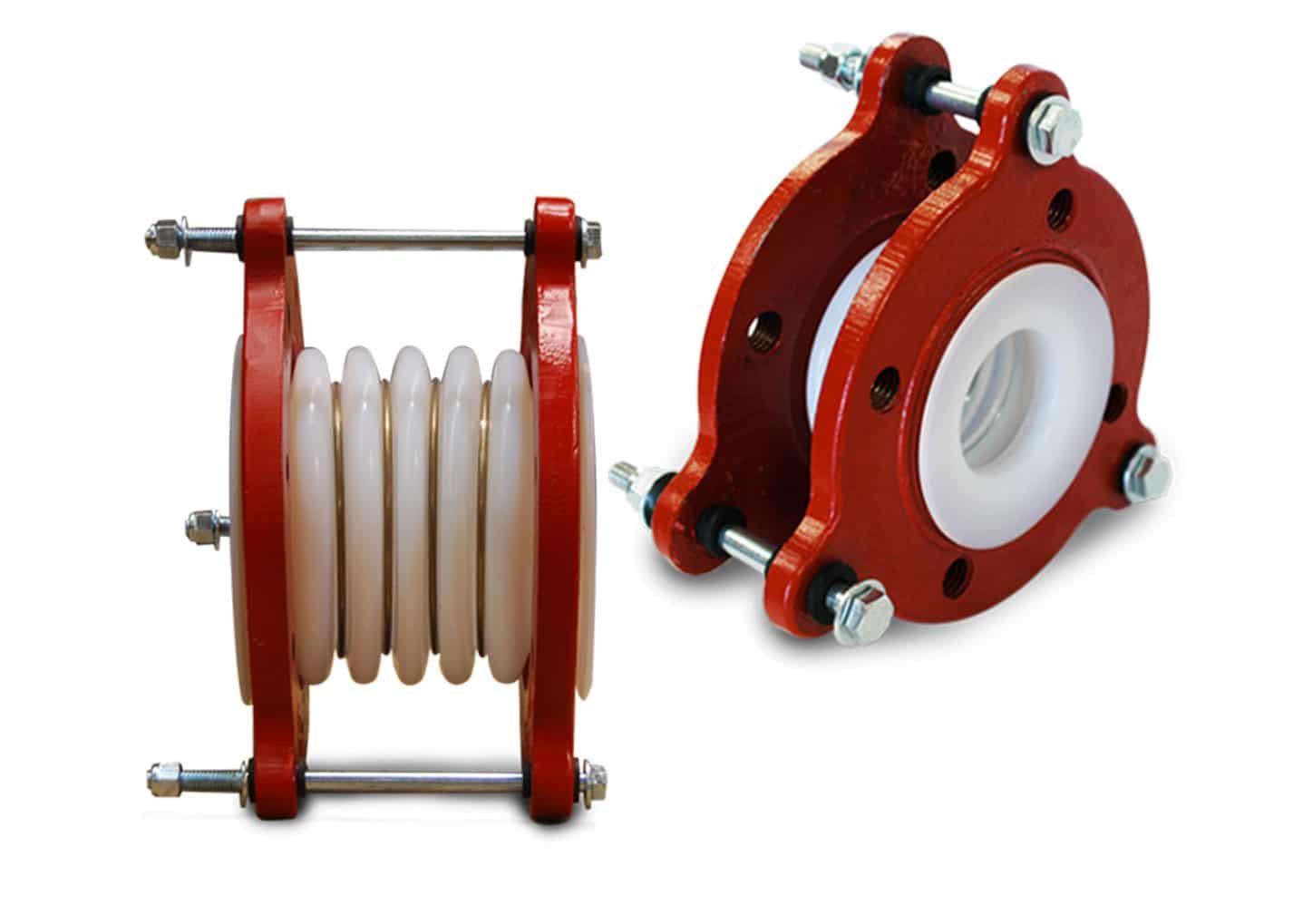

Proco Style 440-BE

The Proco Style 440-BE Molded Expansion Joints can be used for corrosive applications that are found in industries such as chemical-petrochemical, industrial process piping systems, power generation plants, pulp/paper plants, water and wastewater sewage, and pollution control systems. Wherever metallic joints, lap joints, or PTFE and FEP-lined rubber expansion joints were previously used, the Proco Style 440-BE can also be used.

Some notable features of the Proco Style 440 BE include:

- Absorption of pipe-wall and fluid-borne noise

- Reduction of system stress and strain

- Isolation of mechanical vibration and motion

- Superior “Flex Life” and strength

- Tested force pound and spring rate tables

- Coated flanges and factory set limit bolts

- Chemical service capability at minimal cost

- Elimination of electrolysis

- Protection against start up and surge forces

For more information about the features and benefits of the Proco Style 440 BE, download our brochure.

For up-to-date pricing and availability information, contact PROCO today.

| NOMINAL SIZE I.D. | NEUTRAL LENGTH INCHES | MOVEMENT CAPABILITIES 1 | SPRING RATE CAPABILITY2 | EXPANSION JOINT FLANGE DRILLING | PRESSURE AT TEMPERATURE (PSIG) @ ˚F | VACUUM RATING3 | WEIGHT / LBS | ||||||||||||||||||||

| ± AXIAL (∆x) MOVEMENT | LATERAL (∆y) DEFLECTION | ANGULAR DEFLECTION | COMPRESSION SPRING RATE | EXTENSION SPRING RATE | LATERAL SPRING RATE | THRUST FACTOR | # HOLES | THREADED HOLE SIZE | BOLT CIRCLE FLANGE “A” | PTFE FLARE O.D. “B” | FLANGE THICKNESS | NOMINAL FLANGE O.D. | LIMIT BOLT DIAMETER | BOLT CIRCLE LIMIT BOLT “C” | LIMIT BOLT “EAR” O.D. | ||||||||||||

| IN | IN | DEG. | LBf/IN | LBf/IN | LBf/IN | 70˚ | 100˚ | 150˚ | 200˚ | 250˚ | 300˚ | 350˚ | 400˚ | Hg at Temp. | |||||||||||||

| Style 442-BE | |||||||||||||||||||||||||||

| 1.00 | 1.750 | 0.344 | .125 | 7 | 140 | 144 | 120 | 2.76 | 4 | 1/2-13 | 3.125 | 2.000 | .438 | 4.250 | .250 | 5.125 | 6.000 | 185 | 170 | 148 | 130 | 115 | 100 | 84 | 68 | 29.9″ @ 425˚F | 2 |

| 1.50 | 1.813 | 0.344 | .125 | 7 | 240 | 200 | 240 | 4.60 | 4 | 1/2-13 | 3.875 | 2.875 | .469 | 5.000 | .250 | 5.875 | 6.750 | 185 | 170 | 148 | 130 | 115 | 100 | 84 | 68 | 29.9″ @ 425˚F | 2 |

| 2.00 | 1.875 | 0.344 | .125 | 7 | 430 | 350 | 440 | 7.07 | 4 | 5/8-11 | 4.750 | 3.625 | .484 | 6.000 | .375 | 6.875 | 8.125 | 185 | 170 | 148 | 130 | 115 | 100 | 84 | 68 | 29.9″ @ 425˚F | 7 |

| 3.00 | 2.188 | 0.406 | .188 | 7 | 650 | 320 | 350 | 15.90 | 4 | 5/8-11 | 6.000 | 5.000 | .578 | 7.500 | .375 | 8.750 | 10.000 | 185 | 170 | 148 | 130 | 115 | 100 | 84 | 68 | 29.9″ @ 425˚F | 10 |

| 4.00 | 2.281 | 0.438 | .250 | 7 | 360 | 280 | 630 | 23.75 | 8 | 5/8-11 | 7.500 | 6.188 | .578 | 9.000 | .375 | 9.875 | 11.125 | 185 | 170 | 148 | 130 | 115 | 100 | 84 | 68 | 29.9″ @ 400˚F | 18 |

| 6.00 | 2.531 | 0.469 | .250 | 7 | 460 | 350 | 720 | 50.24 | 8 | 3/4-10 | 9.500 | 8.500 | .641 | 11.000 | .500 | 12.500 | 14.000 | 185 | 170 | 148 | 130 | 115 | 100 | 84 | 68 | 29.9″ @ 400˚F | 29 |

| 8.00 | 2.750 | 0.531 | .250 | 7 | 300 | 230 | 800 | 81.48 | 8 | 3/4-10 | 11.750 | 10.625 | .688 | 13.500 | .500 | 14.750 | 16.250 | 164 | 150 | 129 | 112 | 100 | 87 | 73 | 60 | 29.9″ @ 250˚F | 47 |

| 10.00 | 2.969 | 0.563 | .250 | 6 | 1280 | 870 | 1000 | 108.38 | 12 | 7/8-9 | 14.250 | 12.750 | 0.734 | 16.000 | .500 | 17.500 | 19.000 | 164 | 150 | 129 | 112 | 100 | 87 | 73 | 60 | 29.9″ @ 250˚F | 64 |

| 12.00 | 3.094 | 0.594 | .250 | 5 | 380 | 240 | 1000 | 176.63 | 12 | 7/8-9 | 17.000 | 15.000 | 0.813 | 19.000 | .625 | 20.500 | 22.000 | 70 | 59 | 48 | 40 | 35 | 30 | 26 | 22 | 29.9″ @ 75˚F | 115 |

| Style 443-BE | |||||||||||||||||||||||||||

|

1.00 1.50 |

2.313 2.406 |

0.500 0.531 |

.250 .250 |

14 12 |

130 80 |

130 70 |

260 110 |

2.81 5.09 |

4 4 |

1/2-13 1/2-13 |

3.125 3.875 |

2.000 2.875 |

.438 .469 |

4.250 5.000 |

.250 .250 |

5.125 5.875 |

6.000 6.750 |

138 138 |

126 126 |

107 107 |

90 90 |

76 76 |

64 64 |

53 53 |

45 45 |

29.9″ @ 400˚F |

2 4 |

|

2.00 3.00 4.00 |

2.500 2.906 3.063 |

0.531 0.625 0.656 |

.375 .500 .500 |

12 10 10 |

70 140 220 |

80 160 160 |

160 190 190 |

9.11 16.91 25.40 |

4 4 8 |

5/8-11 5/8-11 5/8-11 |

4.750 6.000 7.500 |

3.625 5.000 6.188 |

.484 .578 .578 |

6.000 7.500 9.000 |

.375 .375 .375 |

6.875 8.750 9.875 |

8.125 10.000 11.125 |

138 138 138 |

126 126 126 |

107 107 107 |

90 90 90 |

76 76 76 |

64 64 64 |

53 53 53 |

45 45 45 |

29.9″ @ 400˚F |

8 13 19 |

|

6.00 8.00 |

3.375 3.656 |

0.719 0.781 |

.563 .563 |

9 9 |

350 450 |

190 170 |

540 750 |

50.24 81.48 |

8 8 |

3/4-10 3/4-10 |

9.500 11.750 |

8.500 10.625 |

.641 .688 |

11.000 13.500 |

.500 .500 |

12.500 14.750 |

14.000 16.250 |

138 120 |

126 110 |

107 94 |

90 80 |

76 67 |

64 57 |

53 47 |

45 38 |

29.9″ @ 300˚F |

30 48 |

| Style 445-BE | |||||||||||||||||||||||||||

|

1.00 1.50 |

3.500 3.625 |

0.844 0.785 |

.500 .500 |

20 20 |

50 75 |

110 80 |

50 50 |

2.81 5.09 |

4 4 |

1/2-13 1/2-13 |

3.125 3.875 |

2.000 2.875 |

.438 .469 |

4.250 5.000 |

.250 .250 |

5.125 5.875 |

6.000 6.750 |

72 72 |

61 61 |

46 46 |

40 40 |

34 34 |

29 29 |

27 27 |

24 24 |

NOT DESIGNED FOR VACUUM SERVICE |

2 5 |

|

2.00 3.00 4.00 |

3.750 4.375 4.563 |

0.875 1.031 1.094 |

.500 .500 .625 |

15 17 15 |

60 55 70 |

50 60 60 |

50 170 80 |

9.11 16.91 25.40 |

4 4 8 |

5/8-11 5/8-11 5/8-11 |

4.750 6.000 7.500 |

3.625 5.000 6.188 |

.484 .578 .578 |

6.000 7.500 9.000 |

.375 .375 .375 |

6.875 8.750 9.875 |

8.125 10.000 11.125 |

72 72 72 |

61 61 61 |

46 46 46 |

40 40 40 |

34 34 34 |

29 29 29 |

27 27 27 |

24 24 24 |

9 14 20 |

|

| 6.00 | 5.031 | 1.188 | .625 | 15 | 190 | 130 | 195 | 50.24 | 8 | 3/4-10 | 9.500 | 8.500 | .641 | 11.000 | .500 | 12.500 | 14.000 | 72 | 61 | 46 | 40 | 34 | 29 | 27 | 24 | 31 | |

NOTES:

1. Movements are non-concurrent and based from Neutral Length with Limit Bolts installed.

2. Spring Rate Capability is based on 1″ of movement at zero pressure conditions.

3. Vacuum Rating is based from fully extended position. Style 445-BE is not designed for Vacuum Service.

| PROCO STYLE NUMBER: | STYLE 440-BE MATERIALS OF CONSTRUCTION | ||||||

| 442-BE — 1″ THROUGH 12″ | BELLOWS | FLANGES | REINFORCING RINGS | LIMIT BOLTS | NUTS | GROMMETS | WASHERS |

| 443-BE — 1″ THROUGH 8″ | PTFE T-62 | DUCTILE IRON | STAINLESS STEEL | CARBON STEEL | CARBON STEEL | NEOPRENE | CARBON STEEL |

| 445-BE — 1″ THROUGH 6″ | |||||||