ProFlex™ Style 711

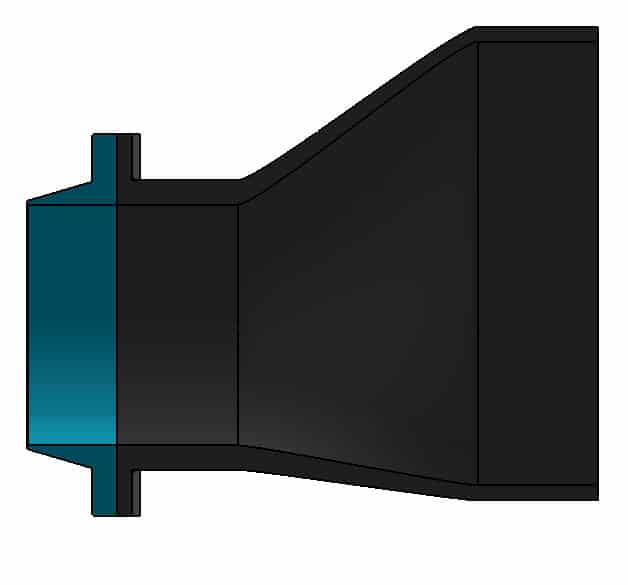

The Proco Style 711 ProFlex™ check valves are engineered for installation on pre-existing pipe lines such as manholes, outfalls and vaults where the outfall invert of the pipe is close to the floor of the manhole or outfall. When a new installation is being designed, the 711 valves can be engineered into the pipe layout with little concern for outfall clearance due to its “low slope” design.

The new Style 711 check valves allow the valves to be installed without any costly and labor-intensive changes to the existing structure. The 711 is engineered to crack open at 1-2” of head pressure and with its unique engineered sloping bottom, the valve ensures zero potential for standing water. With its all elastomer design, the valve can be installed without concern for the future seizing or rusting which can cause premature failure and maintenance issues.

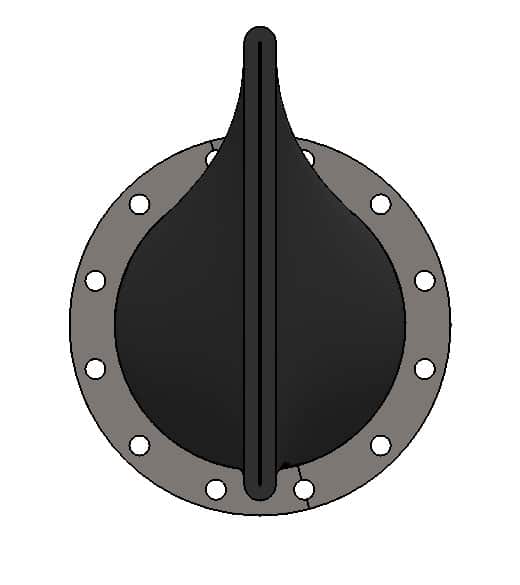

How Does it Work?

The advantage to the Style 711 is the sloping bottom which has been developed to offset the issues commonly affiliated with other flat bottom valves which often entrap solids and flows due to its design. The 711 has been carefully designed to prevent this issue and has a minimal slope which allows complete drainage yet still allows easy installs on minimal clearance areas.

The Style 711 has been engineered to allow a full port which is important in dealing with headloss and jet velocities. The valve is manufactured with 100% algae and barnacle resistant rubber and is also 100% fire resistant.

Advantages:

- Unique bottom slope design ensures 100% drainage

- Installs in flat outfall designs

- Available in both flanged and slip-on design

- An excellent choice for manholes and outfall installation

- Ensures sealing from rubbish and small solids

Materials of Construction

Neoprene, ANSI/NSF-61 certified product elastomers, EPDM and other elastomers available. Please contact Proco.

Mounting Clamps or Retaining Rings

304 or 316 Stainless Steel

For more information about the features and benefits of the Proco ProFlex™ Style 711 rubber duckbill check valve, download our brochure.

For up-to-date pricing and availability information, contact Proco today.

**The ProFlex™ Slope-Bottom Style 711 Check Valves are covered by US PATENT NUMBER 11,221,081**

ProFlex™ 711 Informational Animation

All Proco Series 700 ProFlex™ Rubber Check Valves are available in a various selection of elastomers including ANSI/NSF-61 certified product under UL Certification #MH47689. The Proco Series 700 ProFlex™ Rubber Check Valves will not freeze or deform and function solely on inlet and back pressures which will be present in each unique application.

Each valve is carefully constructed using the finest of materials engineered by some of the most experienced rubber technicians in the industry. All check valves are engineered with precise detail to ensure proper operation and will provide years of unhindered operation and trouble free service.

**The ProFlex™ Slope-Bottom Style 711 Check Valves are covered by US PATENT NUMBER 11,221,081**

Available Styles & Materials

| PROCO Material Code | Cover1,2 Elastomer | Tube Elastomer | Maximum Operating Temp. °F (°C) |

|---|---|---|---|

| BB | Chlorobutyl | Chlorobutyl | 250 °F (121°C) |

| EE | EPDM | EPDM | 250 °F (121°C) |

| NH | Neoprene | CSM | 212 °F (100°C) |

| NN | Neoprene | Neoprene | 225 °F (107°C) |

| NN-NSF61 | Neoprene | Neoprene | 225 °F (107°C) |

| PP | Nitrile | Nitrile | 212 °F (100°C) |

| NR | Neoprene | Natural Rubber | 180 °F (82°C) |

Notes:

ProFlexTM is a trademark of PROCO Products, Inc.

All products are reinforced with polyester tire cord.

1. Styles with Neoprene covers meet all requirements of U.S.C.G

2. NN-NSF/61 UL Classified Water Quality

3. Other Materials available. Please contact Proco Products, Inc.

| Style 711 | |||||||||

| Diameter | Standard Valve Dimensions | Approx. Weight | |||||||

| Length | Duckbill Height | Eccentric Slope | |||||||

| in. | mm | in. | mm | in. | mm | in. | mm | lbs | kgs |

| 4 | 100 | 10.9 | 276 | 8.7 | 222 | 1.0 | 25 | 15 | 6.8 |

| 6 | 150 | 13.3 | 338 | 14.9 | 378 | 2.0 | 50 | 23 | 10.4 |

| 8 | 200 | 14.1 | 359 | 17.9 | 454 | 2.0 | 50 | 36 | 16.3 |

| 10 | 250 | 17.8 | 451 | 20.4 | 518 | 2.0 | 50 | 52 | 23.6 |

| 12 | 300 | 23.8 | 605 | 23.9 | 608 | 2.0 | 50 | 53 | 24.0 |

| 14 | 350 | 25.2 | 640 | 26.7 | 678 | 2.0 | 50 | 64 | 29.0 |

| 16 | 400 | 27.8 | 705 | 31.0 | 788 | 2.0 | 50 | 93 | 42.2 |

| 18 | 450 | 29.9 | 760 | 33.0 | 838 | 2.0 | 50 | 135 | 61.2 |

| 20 | 500 | 30.9 | 785 | 37.7 | 958 | 2.0 | 50 | 155 | 70.3 |

| 24 | 600 | 38.2 | 970 | 43.1 | 1096 | 2.0 | 50 | 235 | 106.6 |

| 30 | 750 | 44.0 | 1118 | 53.2 | 1352 | 3.0 | 76 | 565 | 256.3 |

| 32 | 800 | 45.3 | 1150 | 54.5 | 1384 | 3.0 | 76 | 618 | 280.5 |

| 36 | 900 | 52.4 | 1330 | 66.5 | 1690 | 3.0 | 76 | 725 | 328.9 |

| 40 | 1000 | 52.8 | 1340 | 69.5 | 1766 | 3.0 | 76 | 852 | 386.3 |

| 42 | 1050 | 55.0 | 1398 | 71.6 | 1818 | 3.0 | 76 | 915 | 415.0 |

| 48 | 1200 | 60.6 | 1540 | 81.5 | 2070 | 3.9 | 100 | 1035 | 469.5 |

| 54 | 1350 | 63.6 | 1615 | 89.8 | 2280 | 3.9 | 100 | 1165 | 528.4 |

| 60 | 1500 | 67.5 | 1715 | 94.9 | 2410 | 3.9 | 100 | 1255 | 569.3 |

| 64 | 1600 | 68.5 | 1740 | 101.6 | 2580 | 3.9 | 100 | 1367 | 619.9 |

| 66 | 1650 | 69.7 | 1770 | 103.9 | 2640 | 3.9 | 100 | 1423 | 645.2 |

| 72 | 1800 | 74.8 | 1900 | 115.9 | 2945 | 3.9 | 100 | 1590 | 721.2 |

| 78 | 1950 | 79.1 | 2010 | 124.0 | 3150 | 3.9 | 100 | 1758 | 797.2 |

| 84 | 2100 | 87.8 | 2230 | 125.6 | 3190 | 3.9 | 100 | 1925 | 873.2 |

| 96 | 2400 | 94.9 | 2410 | 137.4 | 3490 | 3.9 | 100 | 2260 | 1025.1 |

NOTES: Higher back pressures can be provided by using internal vacuum supports and/or engineered Hi-Tensile reinforcement. Contact Proco.

1. Dimensions are approximate and may change due to pipe dimensions changes, inlet, back pressures and flow rates.

2. Larger sizes available upon request.

3. Weights are approximate.

**The ProFlexTM Slope-Bottom Style 711 & 731 Check Valves are covered by US PATENT NUMBER 11,221,081**

Due to the wide array of uses for the Proco ProFlex™ Style 711 rubber check valves, it is recommended that you download our Series 700 Brochure to review the Frequently Asked Questions. This will ensure that you choose the proper style of check valve for your specific application.

If additional information is needed, please contact us directly.