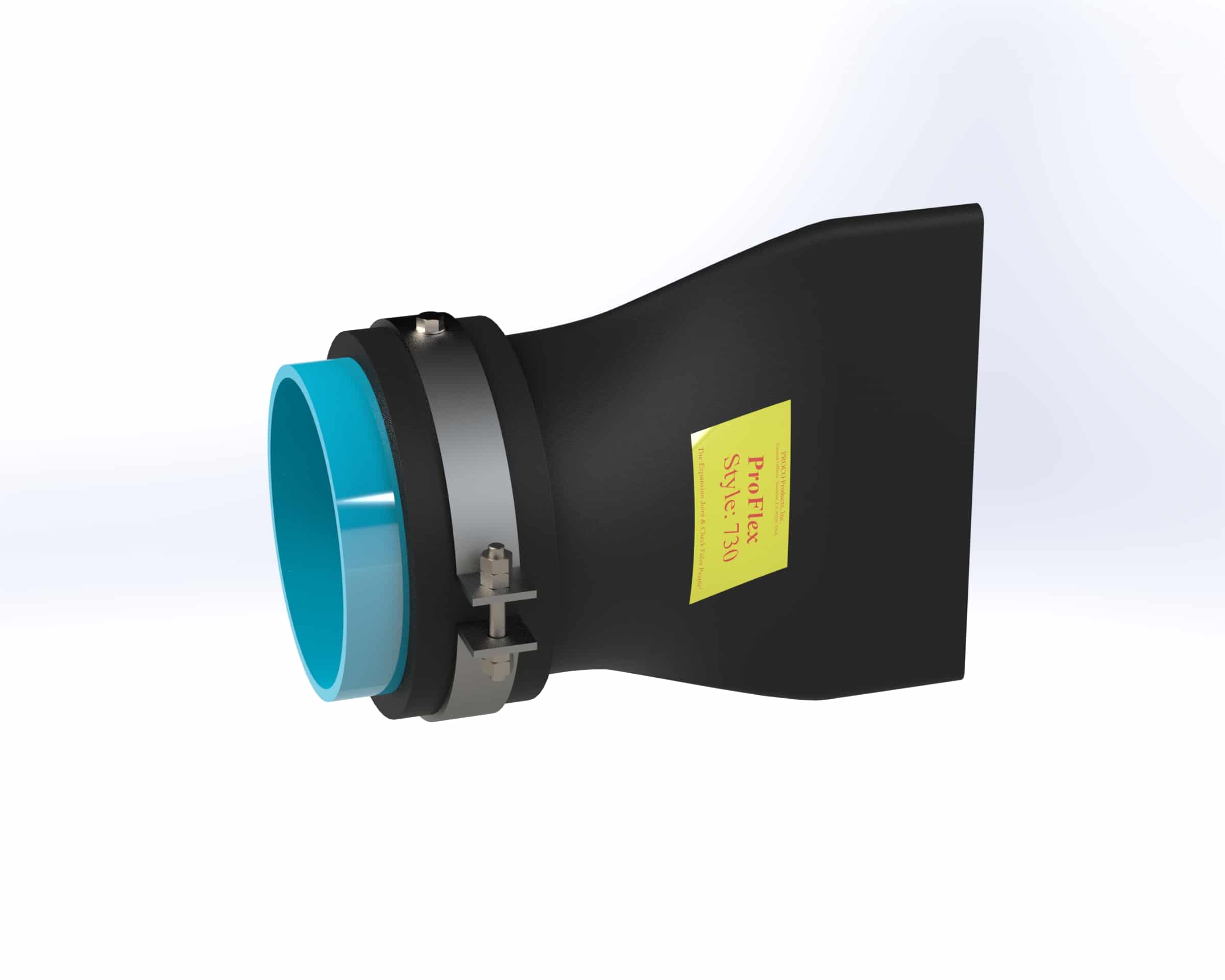

ProFlex™ Style 730

The Proco ProFlex™ Style 730 rubber duckbill check valves are designed to easily slip over an existing pipe and be attached with heavy-duty stainless steel clamps. It can be installed in both vertical and horizontal applications.

Some notable features of the Proco ProFlex™ Style 730 rubber duckbill check valve include:

- All-rubber construction to resist abrasive slurries

- NSF 61 standard construction

- Ultra-quiet operation, with no water hammer

- Unique design to prevent backflow

- Negligible maintenance and energy costs

- Will not warp or freeze

- Quick interchange with any flap type check valve

- Available in sizes from 1” to 96”

- Available with special ID to suit concrete pipe

The rubber duckbill valve creates a low head loss complete with a zero-back flow. The ability of the duckbill valve to prevent backflow into the mating pipe system is a quality aspect in “checking” pipes or tanks that often have problems with back flow problems or odor control.

Proco Products manufactures and supplies rubber duckbill valves to withstand almost any type of media. The most commonly supplied is a barnacle and algae resistant neoprene. Other common elastomers are EPDM, nitrile, natural rubber, and elastomers to meet ANSI/NSF-61 and ANSI/NSF-372 specifications. This includes use for clean water and potable applications and eliminates the concerns commonly affiliated with contaminants or leaching of elastomers in potable water systems.

These duckbill valves offer quiet operation with no water hammer or backflow whilst the all rubber construction resists abrasive slurries. This check valve design has the benefit of negligible maintenance and energy costs. Even in winter conditions if the valve is installed in a running water application, the valve will continue to operate satisfactorily due to the elastomers’ unique chemical makeup. In exceptional low temperatures, the duckbill valve will freeze with the medium without any damage and will return to operation upon thaw. Typically, the elastomers used in Proflex duckbill valves are known to supply 35-50 years of service life.

For more information about the features and benefits of the Proco ProFlex™ Style 730 rubber duckbill check valve, download our brochure.

For up-to-date pricing and availability information, contact Proco today.

All of the Proco Series 700 ProFlex™ Rubber Check Valves, including the ProFlex™ Style 730 duckbill check valve, are available in a various selection of elastomers including ANSI/NSF-61 certified product under UL Certification #MH47689. The Proco Series 700 ProFlex™ Rubber Check Valves will not freeze or deform and function solely on the inlet and back pressures which will be present in each unique application.

Each valve is carefully constructed using the finest of engineered materials by some of the most experienced rubber technicians in the industry. All check valves are engineered in precise detail to ensure proper operation and will provide years of unhindered operation and trouble free service.

Available Styles & Materials

| PROCO Material Code | Cover 1,2 Elastomer | Tube Elastomer | Maximum Operating Temp. °F (°C) |

|---|---|---|---|

| BB | Chlorobutyl | Chlorobutyl | 250 °F (121°C) |

| EE | EPDM | EPDM | 250 °F (121°C) |

| NH | Neoprene | CSM | 212 °F (100°C) |

| NN | Neoprene | Neoprene | 225 °F (107°C) |

| NN-NSF61 | Neoprene | Neoprene | 225 °F (107°C) |

| PP | Nitrile | Nitrile | 212 °F (100°C) |

| NR | Neoprene | Natural Rubber | 180 °F (82°C) |

Notes:

ProFlexTM is a trademark of PROCO Products, Inc.

All products are reinforced with polyester tire cord.

1. Styles with Neoprene covers meet all requirements of U.S.C.G

2. NN-NSF/61 UL Classified Water Quality

3. Other Materials available. Please contact Proco Products, Inc.

| Duckbill Valve Style 730 | |||||||||

| Diameter | Standard Valve Dimensions | Approx. Weight | |||||||

| Cuff Width | Length | Duckbill Height | |||||||

| in. | mm | in. | mm | in. | mm | in. | mm | lbs | kgs |

| 1 | 25 | 1.0 | 25 | 4.1 | 105 | 2.4 | 62 | 1 | 0.3 |

| 1.5 | 40 | 1.0 | 25 | 5.0 | 128 | 3.2 | 82 | 1 | 0.4 |

| 2 | 50 | 1.5 | 38 | 6.1 | 156 | 3.8 | 97 | 3 | 1.2 |

| 2.5 | 65 | 2.0 | 51 | 7.4 | 189 | 4.8 | 122 | 3 | 1.4 |

| 3 | 80 | 3.0 | 76 | 9.5 | 242 | 5.6 | 142 | 5 | 2.3 |

| 4 | 100 | 3.0 | 76 | 12.3 | 313 | 6.9 | 174 | 7 | 3.2 |

| 5 | 125 | 3.0 | 76 | 13.3 | 339 | 9.0 | 228 | 10 | 4.5 |

| 6 | 150 | 4.0 | 102 | 15.7 | 398 | 10.6 | 268 | 13 | 5.8 |

| 8 | 200 | 4.0 | 102 | 17.8 | 452 | 13.7 | 348 | 23 | 10.2 |

| 10 | 250 | 4.0 | 102 | 20.7 | 527 | 16.9 | 428 | 33 | 15.0 |

| 12 | 300 | 6.0 | 152 | 26.3 | 667 | 20.6 | 522 | 59 | 26.8 |

| 14 | 350 | 6.0 | 152 | 28.8 | 732 | 23.7 | 601 | 82 | 37.2 |

| 16 | 400 | 6.0 | 152 | 30.2 | 767 | 27.3 | 693 | 97 | 43.8 |

| 18 | 450 | 6.0 | 152 | 33.1 | 842 | 30.6 | 778 | 209 | 95.0 |

| 20 | 500 | 8.0 | 203 | 36.4 | 925 | 32.6 | 828 | 229 | 104.0 |

| 24 | 600 | 8.0 | 203 | 44.7 | 1136 | 38.0 | 964 | 215 | 97.5 |

| 28 | 700 | 8.0 | 203 | 47.2 | 1198 | 45.3 | 1151 | 365 | 165.6 |

| 30 | 750 | 10.0 | 254 | 51.5 | 1309 | 49.4 | 1254 | 460 | 208.7 |

| 32 | 800 | 10.0 | 254 | 52.5 | 1334 | 51.0 | 1295 | 495 | 224.5 |

| 36 | 900 | 10.0 | 254 | 62.0 | 1574 | 59.5 | 1512 | 585 | 265.4 |

| 40 | 1000 | 10.0 | 254 | 62.0 | 1574 | 65.8 | 1671 | 825 | 374.2 |

| 42 | 1050 | 12.0 | 305 | 65.7 | 1670 | 67.9 | 1725 | 1075 | 487.6 |

| 48 | 1200 | 12.0 | 305 | 73.1 | 1856 | 76.2 | 1935 | 1350 | 612.3 |

| 54 | 1350 | 12.0 | 305 | 77.8 | 1976 | 84.3 | 2140 | 1630 | 739.4 |

| 60 | 1500 | 12.0 | 305 | 83.7 | 2125 | 85.4 | 2170 | 1715 | 777.9 |

| 64 | 1600 | 12.0 | 305 | 86.7 | 2201 | 89.8 | 2280 | 1777 | 805.9 |

| 66 | 1650 | 12.0 | 305 | 89.8 | 2281 | 92.9 | 2360 | 1808 | 819.9 |

| 72 | 1800 | 12.0 | 305 | 97.2 | 2468 | 112.9 | 2868 | 1900 | 861.8 |

| 78 | 1950 | 14.0 | 356 | 99.8 | 2536 | 113.5827 | 2885 | 1993 | 903.8 |

| 84 | 2100 | 14.0 | 356 | 102.0 | 2592 | 117.7165 | 2990 | 2085 | 945.7 |

| 96 | 2400 | 16.0 | 406 | 111.1 | 2822 | 127.5591 | 3240 | 2270 | 1029.7 |

NOTES: Higher back pressures can be provided by using internal vacuum supports and/or engineered Hi-Tensile reinforcement. Contact Proco.

1. Dimensions are approximate and may change due to pipe dimensions changes, inlet, back pressures and flow rates.

2. Larger sizes available upon request.

3. Weights are approximate.

Due to the wide array of uses for the Proco ProFlex™ Style 730 rubber duckbill check valves, it is recommended that you download our Style 730 brochure to review the Frequently Asked Questions. This will ensure that you choose the proper style of check valve for your specific application.

If additional information is needed, please contact us directly.