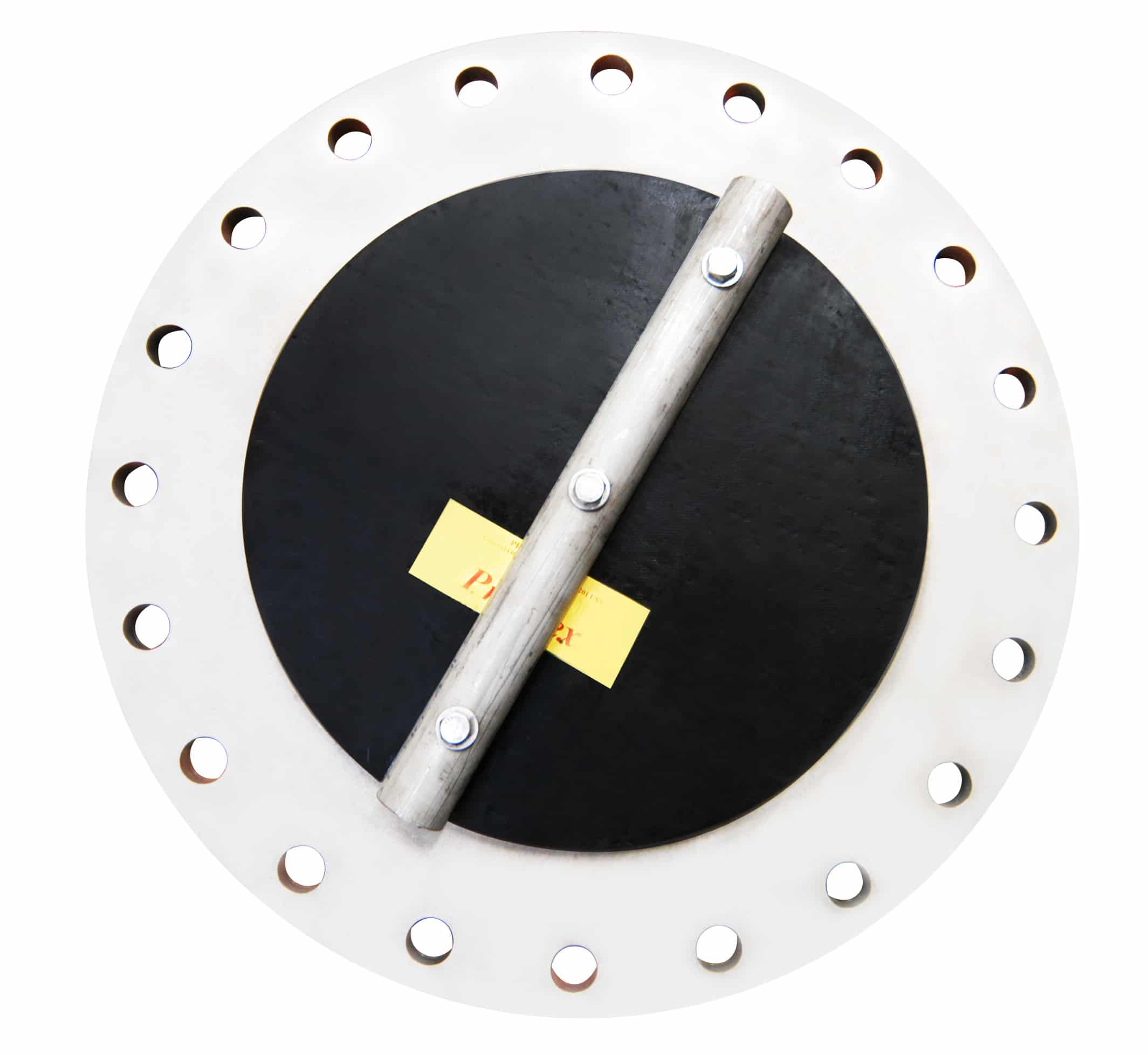

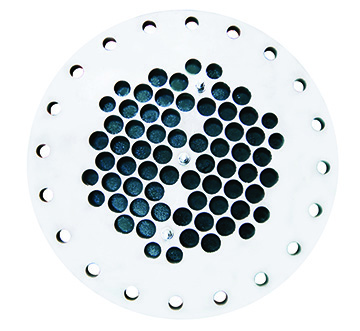

ProFlex™ Style 770/780

The Proco ProFlex™ Style 770 and 780 wafer style rubber check valves feature many design benefits, including:

- All-rubber construction to resist abrasive slurries

- NSF 61 standard construction

- Ultra-quiet operation, with no water hammer

- Unique design to prevent backflow

- Negligible maintenance and energy costs

- Will not warp or freeze

- Quick interchange with any flap type check valve

- Available in sizes from 1” to 96”

- Available with special ID to suit concrete pipe

For more information about the features and benefits of the Proco ProFlex™ Styles 770/780, download our brochure.

For up-to-date pricing and availability information, contact PROCO today.

All Proco Series 700 ProFlex™ Rubber Check Valves are available in a various selection of elastomers including ANSI/NSF-61 certified product under UL Certification #MH47689. The Proco Series 700 ProFlex™ Rubber Check Valves will not freeze or deform and function solely on inlet and back pressures which will be present in each unique application.

Each valve is carefully constructed using the finest of materials engineered by some of the most experienced rubber technicians in the industry. All check valves are engineered with precise detail to ensure proper operation and will provide years of unhindered operation and trouble free service.

Available Styles & Materials

| PROCO Material Code | Cover1,2 Elastomer | Tube Elastomer | Maximum Operating Temp. °F (°C) |

|---|---|---|---|

| BB | Chlorobutyl | Chlorobutyl | 250 °F (121°C) |

| EE | EPDM | EPDM | 250 °F (121°C) |

| NH | Neoprene | CSM | 212 °F (100°C) |

| NN | Neoprene | Neoprene | 225 °F (107°C) |

| NN-NSF61 | Neoprene | Neoprene | 225 °F (107°C) |

| PP | Nitrile | Nitrile | 212 °F (100°C) |

| NR | Neoprene | Natural Rubber | 180 °F (82°C) |

Notes:

ProFlexTM is a trademark of PROCO Products, Inc.

All products are reinforced with polyester tire cord.

1. Styles with Neoprene covers meet all requirements of U.S.C.G

2. NN-NSF/61 UL Classified Water Quality

3. Other Materials available. Please contact Proco Products, Inc.

|

NOMINAL 1 PIPE SIZE |

Standard Dimensions for PROCO Style 770 |

Back Pressure |

VELOCITY (ft/s) vs. HEADLOSS (ft)2 | |||||||

|

Plate Thickness |

Plate O.D. |

1 | 2 | 4 | 6 | 8 | 10 | |||

| 4 | (100) |

0.250 |

6.19 |

150 |

0.40 | 1.29 | 3.97 | 6.18 | 8.17 | 9.83 |

| 6 | (150) |

0.250 |

8.50 |

150 |

0.44 | 1.48 | 4.31 | 6.54 | 8.50 | 10.16 |

| 8 | (200) |

0.375 |

10.63 |

150 |

0.48 | 1.67 | 4.64 | 6.91 | 8.84 | 10.48 |

| 10 | (250) |

0.375 |

12.75 |

150 |

0.52 | 1.86 | 4.98 | 7.27 | 9.17 | 10.81 |

| 12 | (300) |

0.500 |

15.00 |

150 |

0.56 | 2.05 | 5.32 | 7.63 | 9.51 | 11.14 |

| 14 | (350) |

0.500 |

16.25 |

150 |

1.18 | 2.77 | 5.82 | 8.02 | 9.79 | 11.37 |

| 16 | (400) |

0.750 |

18.00 |

150 |

1.80 | 3.50 | 6.33 | 8.41 | 10.08 | 11.60 |

| 18 | (450) |

0.750 |

19.88 |

150 |

2.42 | 4.23 | 6.84 | 8.79 | 10.37 | 11.83 |

| 20 | (500) |

0.750 |

22.00 |

150 |

2.82 | 4.69 | 7.17 | 9.05 | 10.56 | 11.98 |

| 24 | (600) |

1.000 |

27.25 |

150 |

2.86 | 4.75 | 7.24 | 9.12 | 10.64 | 12.06 |

| 30 | (750) |

1.000 |

34.50 |

150 |

2.93 | 4.84 | 7.35 | 9.21 | 10.75 | 12.17 |

| 36 | (900) |

1.000 |

41.00 |

150 |

2.99 | 4.93 | 7.46 | 9.31 | 10.86 | 12.28 |

NOTES: Higher back pressures can be provided by using internal vacuum supports and/or engineered Hi-Tensile reinforcement. Contact Proco.

1. Dimensions are approximate and may change due to pipe dimensions changes, inlet, back pressures and flow rates.

2. Larger sizes available upon request.

3. Weights are approximate.

|

NOMINAL 1 PIPE SIZE |

Standard Dimensions for PROCO Style 780 |

Back Pressure |

VELOCITY (ft/s) vs. HEADLOSS (ft)2 | ||||||||||

|

Plate Thickness |

Flange O.D. |

Bolt Circle |

No. of Holes |

Size of Holes |

1 | 2 | 4 | 6 | 8 | 10 | |||

| 4 | (100) |

0.250 |

9.00 |

7.50 |

8 |

0.750 |

150 |

0.40 | 1.29 | 3.97 | 6.18 | 8.17 | 9.83 |

| 6 | (150) |

0.250 |

11.00 |

9.50 |

8 |

0.875 |

150 |

0.44 | 1.48 | 4.31 | 6.54 | 8.50 | 10.16 |

| 8 | (200) |

0.375 |

13.50 |

11.75 |

8 |

0.875 |

150 |

0.48 | 1.67 | 4.64 | 6.91 | 8.84 | 10.48 |

| 10 | (250) |

0.375 |

16.00 |

14.25 |

12 |

1.000 |

150 |

0.52 | 1.86 | 4.98 | 7.27 | 9.17 | 10.81 |

| 12 | (300) |

0.500 |

19.00 |

17.00 |

12 |

1.000 |

150 |

0.56 | 2.05 | 5.32 | 7.63 | 9.51 | 11.14 |

| 14 | (350) |

0.500 |

21.00 |

18.75 |

12 |

1.250 |

150 |

1.18 | 2.77 | 5.82 | 8.02 | 9.79 | 11.37 |

| 16 | (400) |

0.750 |

23.50 |

21.25 |

16 |

1.250 |

150 |

1.80 | 3.50 | 6.33 | 8.41 | 10.08 | 11.60 |

| 18 | (450) |

0.750 |

25.00 |

22.75 |

16 |

1.250 |

150 |

2.42 | 4.23 | 6.84 | 8.79 | 10.37 | 11.83 |

| 20 | (500) |

0.750 |

27.50 |

25.00 |

20 |

1.250 |

150 |

2.82 | 4.69 | 7.17 | 9.05 | 10.37 | 11.98 |

| 24 | (600) |

1.000 |

32.00 |

29.50 |

20 |

1.375 |

150 |

2.86 | 4.75 | 7.24 | 9.12 | 10.56 | 12.06 |

| 30 | (750) |

1.000 |

38.75 |

36.00 |

28 |

1.375 |

150 |

2.93 | 4.84 | 7.35 | 9.21 | 10.75 | 12.17 |

| 36 | (900) |

1.000 |

46.00 |

42.75 |

32 |

1.625 |

150 |

2.99 | 4.93 | 7.46 | 9.31 | 10.86 | 12.28 |

NOTES: Higher back pressures can be provided by using internal vacuum supports and/or engineered Hi-Tensile reinforcement. Contact Proco.

1. Dimensions are approximate and may change due to pipe dimensions changes, inlet, back pressures and flow rates.

2. Larger sizes available upon request.

3. Weights are approximate.

Due to the wide array of uses for the Proco ProFlex™ Styles 770 and 780 rubber check valves, it is recommended that you download our Style 770/780 brochure to review the Frequently Asked Questions. This will ensure that you choose the proper style of check valve for your specific application.

If additional information is needed, please contact us directly.