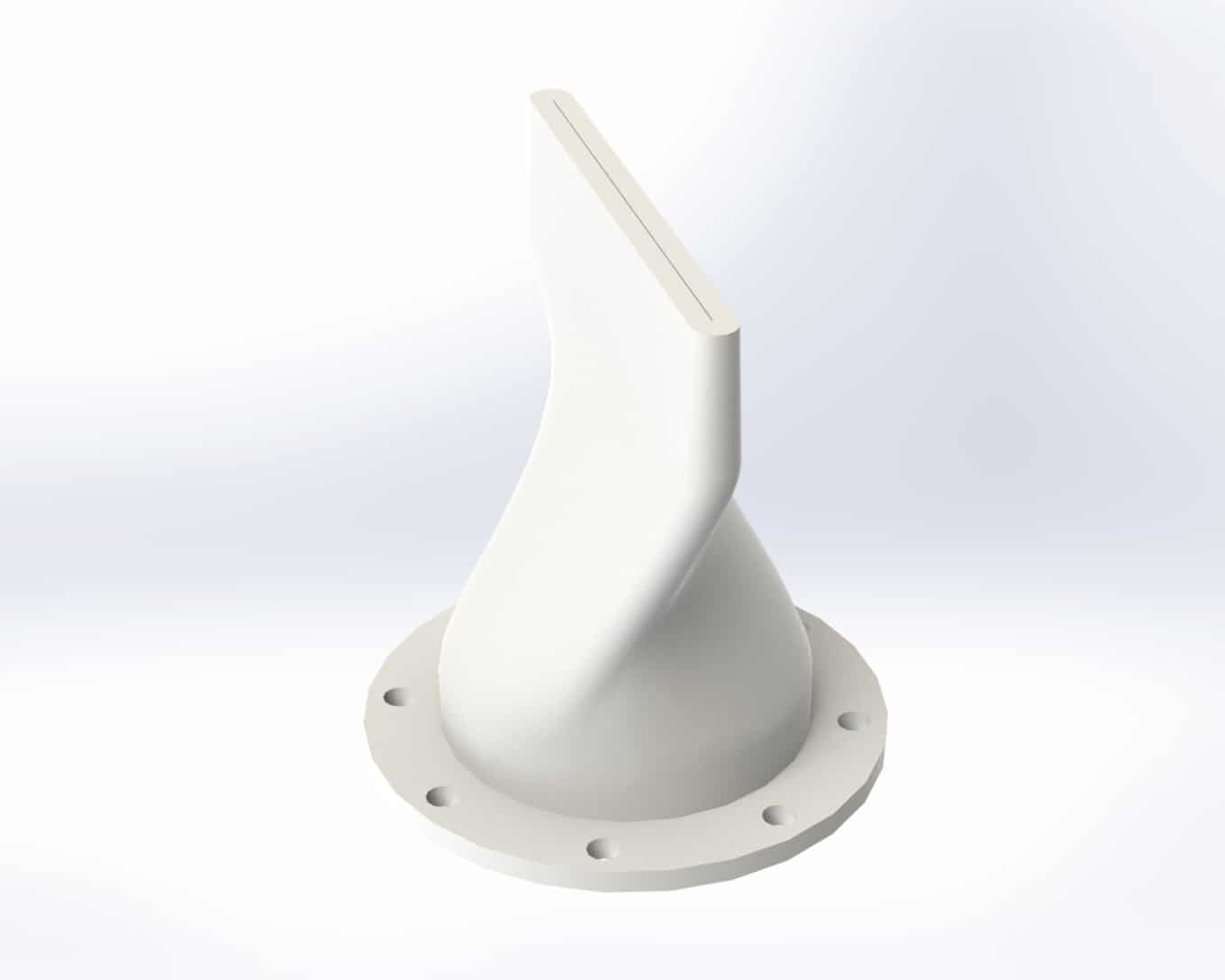

ProFlex™ Style 710TT

The ProFlex™ 710TT has been engineered and developed to be the most efficient and specifiable valve to ensure 100% mixing capability in potable water and sewage reservoir/storage tanks.

Under U.S. Patent No. 11,396,951, the new patented torsional flow design of the valve provides a unique spinning motion which has never been offered before and is a stand-alone feature. Its operational values require less head pressure and less pump energy, thus saving the client money as well as less time to mix!

When inlet pressure is applied to the designed manifold in any reservoir, the intent is to ensure an adequate mixing of the media by blending the different temperature variations into one, thus eliminating hot spots which is an ongoing concern in potable water reservoirs.

The ProFlex™ 710TT, with its torsional design, has been found to also require fewer valves to adequately mix a volume of water compared to other valves available on the market. This has allowed us to engineer, manufacture and provide 3 main pipe diameters of valves, ( 4”, 6” and 8”) therefore ensuring that the 710TT will be a readily available “off the shelf” valve.

Where Will We Use These Systems & What Are The Cost Saving Advantages?

• All potable water reservoirs or tanks require mixing if the concern of

foul or stagnant water is possible.

• All sewage reservoirs or tanks also require mixing if sludge settling is

a concern.

• All of the ProFlex™ 710TT’s along with the ProFlex™ 780/770 valves,

use passive energy only to properly mix a system, no additional power

sources are required.

• All ProFlex™ 710TT’s will have CFD modeling available to validate all

tank styles.

• ANSI/NSF-61 certified valves are a standard.

• Zero maintenance/No mechanical parts.

• The intent of the ProFlex™ system is to ensure that all areas of a tank/

reservoir are properly mixed without the requirement of additional

tank penetrations, ensuring less chance of external leakages and a

definite cost savings.

• Life expectancy is 35-50 years

For more information about the features and benefits of the Proco ProFlex™ Style 710TT rubber duckbill check valve, download our brochure.

For up-to-date pricing and availability information, contact Proco today.

All Proco Series 700 ProFlex™ Rubber Check Valves are available in a various selection of elastomers including ANSI/NSF-61 certified product under UL Certification #MH47689. The Proco Series 700 ProFlex™ Rubber Check Valves will not freeze or deform and function solely on inlet and back pressures which will be present in each unique application.

Each valve is carefully constructed using the finest of materials engineered by some of the most experienced rubber technicians in the industry. All check valves are engineered with precise detail to ensure proper operation and will provide years of unhindered operation and trouble free service.

Available Styles & Materials

| PROCO Material Code | Cover Elastomer | Tube Elastomer | Maximum Operating Temp. °F (°C) |

|---|---|---|---|

| BB | Chlorobutyl | Chlorobutyl | 250 °F (121°C) |

| EE | EPDM | EPDM | 250 °F (121°C) |

| NH | Neoprene | CSM | 212 °F (100°C) |

| NN | Neoprene | Neoprene | 225 °F (107°C) |

| NN-NSF61 | Neoprene | Neoprene | 225 °F (107°C) |

| PP | Nitrile | Nitrile | 212 °F (100°C) |

| NR | Neoprene | Natural Rubber | 180 °F (82°C) |

Notes:

ProFlexTM is a trademark of PROCO Products, Inc.

All products are reinforced with polyester tire cord.

1. Styles with Neoprene covers meet all requirements of U.S.C.G

2. NN-NSF/61 UL Classified Water Quality

3. Other Materials available. Please contact Proco Products, Inc.

|

Diameter |

Standard Dimensions for PROCO Style 710TT |

Flange Detail |

||

|

Length |

Duckbill Height |

|||

| 4 | (100) |

10.5 |

7.4 |

ANSI 150# |

| 6 | (150) |

12.8 |

10.8 |

ANSI 150# |

| 8 | (200) |

15.0 |

13.8 |

ANSI 150# |

Other sizes available. Please Contact Proco

Due to the wide array of uses for the Proco ProFlex™ Style 710TT Flanged Blending System Valves, it is recommended that you download our Style 7710TT brochure to review the Frequently Asked Questions. This will ensure that you choose the proper style of check valve for your specific application.

If additional information is needed, please contact us directly.